DeFelsko PosiTector UTG

DeFelsko PosiTector UTG Ultrasonic Wall Thickness Gauges

Ultrasonic Wall Thickness Gauges (ultrasonic thickness gauges, ultrasonic thickness testers, ultrasonic thickness meters, UT gauges, etc.) measure the wall thickness of materials such as steel, plastic, and more using ultrasonic technology. PosiTector UTG Ultrasonic Thickness Gauges are ideal for measuring the effects of corrosion or erosion on tanks, pipes, or any structure where access is limited to one side. Multiple echo Thru-Paint models (PosiTector UTG M) measure the metal thickness of a painted structure without having to remove the coating.

|

Conforms to ASTM E797

What is Ultrasonic Thickness Measurement?

Ultrasonic thickness measurement techniques are used to measure a wide range of substrates and applications for loss of material thickness due to corrosion or erosion. Ultrasonic Thickness Gauges are designed for measuring the thickness of metallic (cast iron, steel and aluminum) and non-metallic (ceramics, plastics and glass) substrates and any other ultrasonic wave-conductor provided it has relatively parallel top and bottom surfaces.

An ultrasonic thickness gauge facilitates rapid inspection of the thickness of large metallic structures at small measurement intervals, providing a high-detail thickness map of a scanned surface. When access is only available from one side of the substrate, ultrasonic wall thickness measurement is the most efficient way to monitor the effects of erosion or corrosion and is instrumental to both quality assurance and quality control.

Ultrasonic Thickness Gauges – Corrosion - PosiTector UTG C Series

|

|

|

PosiTector UTG C |

PosiTector UTG CA Corrosion with Integral Probe |

PosiTector UTG CX Corrosion with Xtreme Probe |

Ultrasonic Thickness Gauges – Thru-Paint UT Thickness Gauge - PosiTector UTG M

Ultrasonic Thickness Gauges – Cast Iron - PosiTector UTG CLF

Ultrasonic Thickness Gauges - Precision - PosiTector UTG P

DeFelsko PosiTector UTG Ultrasonic Wall Thickness Gages: 6 STANDARD MODELS AVAILABLE

|

|

|

| DeFelsko PosiTector UTG C1 | DeFelsko PosiTector UTG CA1 | DeFelsko PosiTector UTG CX1 |

| READING STORAGE CAPACITY | READING STORAGE CAPACITY | READING STORAGE CAPACITY |

| 1,000 per probe | 1,000 per probe | 1,000 per probe |

| INCLUDES WIFI AND BLUETOOTH | INCLUDES WIFI AND BLUETOOTH | INCLUDES WIFI AND BLUETOOTH |

| No | No | No |

| PROBE TYPE | PROBE TYPE | PROBE TYPE |

| 5 MHz Dual Element | 5 MHz Dual Element | 5 MHz Dual Element |

| THRU-PAINT CAPABILITY | THRU-PAINT CAPABILITY | THRU-PAINT CAPABILITY |

| No | No | No |

| MEASURING RANGE* | MEASURING RANGE* | MEASURING RANGE* |

| 0.040" to 5.000" 1.00 to 125.00 mm |

0.040" to 5.000" 1.00 to 125.00 mm |

0.040" to 5.000" 1.00 to 125.00 mm |

| ACCURACY | ACCURACY | ACCURACY |

| ± 0.001" ± 0.03 mm |

± 0.001" ± 0.03 mm |

± 0.001" ± 0.03 mm |

![]()

|

|

|

| DeFelsko PosiTector UTG CLF1^ | DeFelsko PosiTector UTG M1 | DeFelsko PosiTector UTG P1 |

| READING STORAGE CAPACITY | READING STORAGE CAPACITY | READING STORAGE CAPACITY |

| 1,000 per probe | 1,000 per probe | 1,000 per probe |

| INCLUDES WIFI AND BLUETOOTH | INCLUDES WIFI AND BLUETOOTH | INCLUDES WIFI AND BLUETOOTH |

| No | No | No |

| PROBE TYPE | PROBE TYPE | PROBE TYPE |

| 2.25 MHz Dual Element | 5 MHz Contact | 15 MHz Single Element Delay Line |

| THRU-PAINT CAPABILITY | THRU-PAINT CAPABILITY | THRU-PAINT CAPABILITY |

| No | Yes | Yes |

| MEASURING RANGE* - MULTIPLE ECHO | SINGLE ECHO MEASURING RANGE* | STEEL MEASURING RANGE* |

| NA | 0.100" to 5.000" 2.50 to 125.00 mm |

0.008" to 0.475" 0.2 to 12.0 mm |

| MEASURING RANGE* | MULTIPLE ECHO MEASURING RANGE* | PLASTIC MEASURING RANGE* |

| 0.080" to 5.000" 2.00 to 125.00 mm |

0.100" to 2.500" 2.50 to 60.00 mm |

0.005" to 0.175" 0.125 to 4.500 mm |

| ACCURACY | ACCURACY | ACCURACY |

| ± 0.001" ± 0.03 mm |

± 0.001" ± 0.03 mm |

± 0.0004" ±0.01 mm |

^ 2.25 MHz Dual Element transducer with cabled probe, designed for measuring attenuative materials such as cast iron

* Measurement range is for carbon steel and depends upon surface condition, temperature and material.

DeFelsko PosiTector UTG Ultrasonic Wall Thickness Gages: 6 ADVANCED MODELS AVAILABLE

|

|

|

| DeFelsko PosiTector UTG C3 | DeFelsko PosiTector UTG CA3 | DeFelsko PosiTector UTG CX3 |

| READING STORAGE CAPACITY | READING STORAGE CAPACITY | READING STORAGE CAPACITY |

| 250,000 in up to 1,000 batches | 250,000 in up to 1,000 batches | 250,000 in up to 1,000 batches |

| INCLUDES WIFI AND BLUETOOTH | INCLUDES WIFI AND BLUETOOTH | INCLUDES WIFI AND BLUETOOTH |

| Yes | Yes | Yes |

| PROBE TYPE | PROBE TYPE | PROBE TYPE |

| 5 MHz Dual Element | 5 MHz Dual Element | 5 MHz Dual Element |

| THRU-PAINT CAPABILITY | THRU-PAINT CAPABILITY | THRU-PAINT CAPABILITY |

| No | No | No |

| MEASURING RANGE* | MEASURING RANGE* | MEASURING RANGE* |

| 0.040" to 5.000" 1.00 to 125.00 mm |

0.040" to 5.000" 1.00 to 125.00 mm |

0.040" to 5.000" 1.00 to 125.00 mm |

| ACCURACY | ACCURACY | ACCURACY |

| ± 0.001" ± 0.03 mm |

± 0.001" ± 0.03 mm |

± 0.001" ± 0.03 mm |

![]()

|

|

|

| DeFelsko PosiTector UTG CLF3^ | DeFelsko PosiTector UTG M3 | DeFelsko PosiTector UTG P3 |

| READING STORAGE CAPACITY | READING STORAGE CAPACITY | READING STORAGE CAPACITY |

| 250,000 in up to 1,000 batches | 250,000 in up to 1,000 batches | 250,000 in up to 1,000 batches |

| INCLUDES WIFI AND BLUETOOTH | INCLUDES WIFI AND BLUETOOTH | INCLUDES WIFI AND BLUETOOTH |

| Yes | Yes | Yes |

| PROBE TYPE | PROBE TYPE | PROBE TYPE |

| 2.25 MHz Dual Element | 5 MHz Contact | 15 MHz Single Element Delay Line |

| THRU-PAINT CAPABILITY | THRU-PAINT CAPABILITY | THRU-PAINT CAPABILITY |

| No | Yes | Yes |

| MEASURING RANGE* - MULTIPLE ECHO | SINGLE ECHO MEASURING RANGE* | STEEL MEASURING RANGE* |

| NA | 0.100" to 5.000" 2.50 to 125.00 mm |

0.008" to 0.475" 0.2 to 12.0 mm |

| MEASURING RANGE* | MULTIPLE ECHO MEASURING RANGE* | PLASTIC MEASURING RANGE* |

| 0.080" to 5.000" 2.00 to 125.00 mm |

0.100" to 2.500" 2.50 to 60.00 mm |

0.005" to 0.175" 0.125 to 4.500 mm |

| ACCURACY | ACCURACY | ACCURACY |

| ± 0.001" ± 0.03 mm |

± 0.001" ± 0.03 mm |

± 0.0004" ±0.01 mm |

^ 2.25 MHz Dual Element transducer with cabled probe, designed for measuring attenuative materials such as cast iron

* Measurement range is for carbon steel and depends upon surface condition, temperature and material.

DeFelsko PosiTector UTG Ultrasonic Wall Thickness Gages: PROBE ORDER GUIDE

|

|

|

| DeFelsko PosiTector PRBUTGC | DeFelsko PosiTector PRBUTGCA | DeFelsko PosiTector PRBUTGCX |

| PROBE TYPE | PROBE TYPE | PROBE TYPE |

| 5 MHz Dual Element | 5 MHz Dual Element | 5 MHz Dual Element |

| THRU-PAINT CAPABILITY | THRU-PAINT CAPABILITY | THRU-PAINT CAPABILITY |

| No | No | No |

| MEASURING RANGE* | MEASURING RANGE* | MEASURING RANGE* |

| 0.040" to 5.000" 1.00 to 125.00 mm |

0.040" to 5.000" 1.00 to 125.00 mm |

0.040" to 5.000" 1.00 to 125.00 mm |

| ACCURACY | ACCURACY | ACCURACY |

| ± 0.001" ± 0.03 mm |

± 0.001" ± 0.03 mm |

± 0.001" ± 0.03 mm |

![]()

|

|

|

| DeFelsko PosiTector PRBUTGCLF^ | DeFelsko PosiTector PRBUTGM | DeFelsko PosiTector PRBUTGP |

| PROBE TYPE | PROBE TYPE | PROBE TYPE |

| 2.25 MHz Dual Element | 5 MHz Contact | 15 MHz Single Element Delay Line |

| THRU-PAINT CAPABILITY | THRU-PAINT CAPABILITY | THRU-PAINT CAPABILITY |

| No | Yes | Yes |

| MEASURING RANGE* - MULTIPLE ECHO | SINGLE ECHO MEASURING RANGE* | STEEL MEASURING RANGE* |

| NA | 0.100" to 5.000" 2.50 to 125.00 mm |

0.008" to 0.475" 0.2 to 12.0 mm |

| MEASURING RANGE* | MULTIPLE ECHO MEASURING RANGE* | PLASTIC MEASURING RANGE* |

| 0.080" to 5.000" 2.00 to 125.00 mm |

0.100" to 2.500" 2.50 to 60.00 mm |

0.005" to 0.175" 0.125 to 4.500 mm |

| ACCURACY | ACCURACY | ACCURACY |

| ± 0.001" ± 0.03 mm |

± 0.001" ± 0.03 mm |

± 0.0004" ±0.01 mm |

^ 2.25 MHz Dual Element transducer with cabled probe, designed for measuring attenuative materials such as cast iron

* Measurement range is for carbon steel and depends upon surface condition, temperature and material.

DeFelsko PosiTector Gage Bodies: FEATURE COMPARISON CHART

For use with the: DeFelsko PosiTector 6000, DeFelsko PosiTector 200, DeFelsko PosiTector SPG, DeFelsko PosiTector RTR H, DeFelsko PosiTector RTR 3D, DeFelsko PosiTector DPM, DeFelsko PosiTector IRT, DeFelsko PosiTector SST , DeFelsko PosiTector UTG, DeFelsko PosiTector SHD, DeFelsko PosiTector BHI

Video

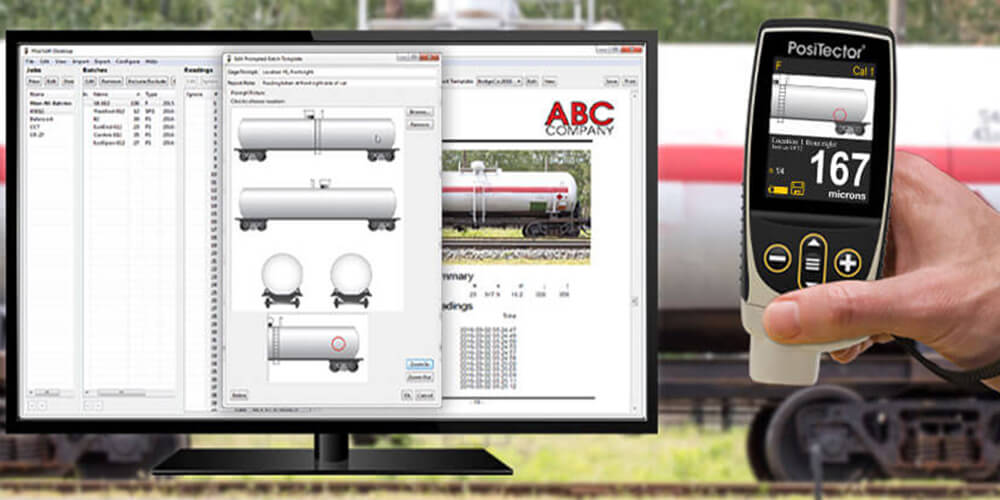

PosiSoft Suite of Software

Four FREE and unique ways to view and report your PosiTector and PosiTest data. Learn More

|

|

DeFelsko Accessories

Accessories for DeFelsko Inspection Instruments - Online Catalog

The DeFelsko PosiTector UTG Ultrasonic Wall Thickness Gauges measure the wall thickness of materials such as steel, plastic, and more using ultrasonic technology. PosiTector UTG Ultrasonic Thickness Gauges are ideal for measuring the effects of corrosion or erosion on tanks, pipes, or any structure where access is limited to one side. Multiple echo Thru-Paint models (PosiTector UTG M) measure the metal thickness of a painted structure without having to remove the coating.

- Precision ultrasonic transducers provide fast, accurate readings

- NEW Larger 2.8" impact resistant color touchscreen with redesigned keypad for quick menu navigation

- NEW Weatherproof, dustproof, and water-resistant—IP65-rated enclosure

- Pre-programmed velocities—Simply select from a list of common materials or enter your own with ease

- Min Scan mode—take continuous readings and record min/max thicknesses — ideal for quick inspection

- PosiTector interchangeable platform—attach any PosiTector probe to a single gage body

- USB, WiFi, and Bluetooth connectivity to PosiSoft PC, Mac, and Smartphone software

Conforms to ASTM E797

F.A.Q.

Do your instruments require any formal training for use? Do you offer ‘demo’ models?

No. Our instruments are designed for simple operation, feature easy-to-use menus, both full and quick instruction manuals, and helpful videos. In lieu of demonstration models, we provide unlimited technical support via telephone and/or email, and a limited 30-day money back guarantee.

Is the PosiTector UTG calibrated at the factory?

The PosiTector UTG arrives fully calibrated and ready to measure. A Long-Form Certificate of Calibration traceable to NIST is included, which documents actual readings taken by your instrument at our calibration laboratory on standards traceable to a national metrology institute. Beware of ‘Certificates’ or ‘Certificates of Conformance’ offered by competitors. These typically do not include actual instrument readings, and are often insufficient to meet common quality equirements.Verification of gage calibration and accuracy can be performed with the accessory Certified Step Block. If necessary, the PosiTector UTG operator can easily perform a calibration adjustment to align the gage’s thickness readings to match that of a known reference sample.

Can I measure the thickness of non-metallic materials like plastic and rubber with the PosiTector UTG?

Yes! The PosiTector UTG features several preprogrammed sound velocities for common materials. For best accuracy, make a simple adjustment to a known sample thickness of the material or quickly enter the material’s sound velocity into the gage. The PosiTector UTG C can be adjusted to a broad range of sound velocities spanning from 0.0492 to 0.393 mils/µs (1250 to 10000 m/s).

Can the PosiTector UTG measure cast/ductile iron or cast aluminum?

Our PosiTector UTG ultrasonic wall thickness instruments are designed to accurately measure the wall thickness of carbon steel, aluminum, stainless steel and plastic.PosiTector UTG probes utilize a 5MHz transducer. Like other UT (ultrasonic wall thickness) gages utilizing a 5MHz transducer, the PosiTector UTG is challenged to provide reliable wall thickness measurements on cast metals including iron, aluminum and zinc. The internal structure of the cast metal typically interferes with the transmission of a 5MHz sound impulse causing the gage to yield inaccurate thickness readings.

What is the difference between the PosiTector UTG C and PosiTector UTG M?

The PosiTector UTG C (Corrosion) single echo probe uses a dual-element transducer, a focused “V-path”, and V-path compensation to accurately measure the thickness of metals with particularly heavy corrosion or pitting. The UTG C single echo probe will not ignore the thickness of the exterior coating: for best measurement accuracy, it may be necessary to remove any coating present at the point of measurement.The PosiTector UTG M (Multi-echo) probe uses a single element transducer to accurately measure the metal thickness of a new or lightly corroded structure while ignoring the thickness of protective coatings. The ultrasonic beam travels in a straight path to the material’s back wall at 90° relative to the surface. When three consecutive back wall echoes are detected, the probe makes a time-based calculation to eliminate the coating thickness from the gage reading.

If there is paint on the surface and it can’t be removed, can the PosiTector UTG C be used?

Yes, but coatings such as paint have a slower sound velocity than metal. This means that coating ‘appears’ much thicker to the instrument than it actually is, and can substantially affect the reading. Using Thru-Paint technology, the PosiTector UTG M multi-echo probe disregards the exterior coating thickness on a painted metal structure and reports only the metal thickness.

Can the UTG measure the thickness of materials with heavy corrosion on the back/inside?

The PosiTector UTG C (Corrosion) is a proven solution for measuring the thickness of metal structures with pitting and/or moderate-to-severe corrosion on the back wall.

How often should the PosiTector probe be recalibrated?

PosiTector probes include a Certificate of Calibration with no expiry or end date. They have no shelf life, therefore the length of time in the field is not a good indicator for recalibration intervals. Many organizations with quality programs and recertification programs require annual recalibrations, and this is a good starting point for most users. Manufacturers recommend that customers establish calibration intervals based upon their own experience and work environment. Based on our product knowledge, data and customer feedback, a one year calibration interval from the date the instrument was placed in service is a good starting point.

DeFelsko UTGC1-G PosiTector UTG C1 Standard Ultrasonic Thickness Gage with Cable...

- DeFelsko UTGC1-G PosiTector UTG C1 Standard Ultrasonic Thickness Gage with PRBUTGC-C Corrosion Probe, 5 MHz Dual Element

- Measuring Range: 0.040" - 5.000" (1.00 - 125 mm)

- Available in Standard and Thru-Paint(Multiple Echo) models

View More Details

DeFelsko UTGCA1-G PosiTector UTG CA1 Standard Ultrasonic Thickness Gage Integral...

- DeFelsko UTGCA1-G PosiTector UTG CA1 Standard Ultrasonic Thickness Gage with Integral Probe, 5 MHz Dual Element

- Measuring Range: 0.040" to 5.000" - 1.00 to 125.00 mm

View More Details

DeFelsko UTGCX1-G PosiTector UTG CX1 Standard Ultrasonic Thickness Gage with Xtr...

- DeFelsko UTGCX1-G PosiTector UTG CX1 Standard Ultrasonic Thickness Gage with PRBUTGCX-C Xtreme Corrosion Probe, 5 MHz Dual Element

- Measuring Range: 0.040" - 5.000" (1.00 - 125 mm)

View More Details

DeFelsko UTGCLF1-G PosiTector UTG CLF1 Standard Ultrasonic Thickness Gage with L...

- DeFelsko UTGCLF1-G PosiTector UTG CLF1 Standard Ultrasonic Thickness Gage with Low Frequency Probe , 2.25 MHz Dual Element

- Measuring Range: 0.080" to 5.000" - 2.00 to 125.00mm

View More Details

DeFelsko UTGM1-G PosiTector UTG M1 Standard Ultrasonic Thickness Gage with Multi...

- DeFelsko UTGM1-G PosiTector UTG M1 Standard Ultrasonic Thickness Gage with PRBUTGM-C Multiple Echo Probe, 5 MHz Contact

- Measuring Range Multiplo Echo: 0.100" to 2.500" (2.50 to 60.00 mm)

- Thru-Paint Capability (Multiple Echo): Measures the metal thickness of a painted structure without having to remove the coating.

View More Details

DeFelsko UTGP1-G PosiTector UTG P1 Standard Ultrasonic Thickness Gage with Preci...

- DeFelsko UTGP1-G PosiTector UTG P1 Standard Ultrasonic Thickness Gage with Precision Probe, 15 MHz Single Element Delay Line

- Steel Measuring Range: 0.008" to 0.475" - 0.2 to 12.0 mm | Plastic Measuring Range: 0.005" to 0.175" - 0.125 to 4.500 mm

View More Details

DeFelsko UTGC3-G PosiTector UTG C3 Advanced Ultrasonic Thickness Gage with Cable...

- DeFelsko UTGC3-G PosiTector UTG C3 Advanced Ultrasonic Thickness Gage with PRBUTGC-C Corrosion Probe, 5 MHz Dual Element

- Measuring Range: 0.040" - 5.000" (1.00 - 125 mm)

View More Details

DeFelsko UTGCA3-G PosiTector UTG CA3 Advanced Ultrasonic Thickness Gage Integral...

- DeFelsko UTGCA3-G PosiTector UTG CA3 Advanced Ultrasonic Thickness Gage with Integral Probe, 5 MHz Dual Element

- Measuring Range: 0.040" to 5.000" - 1.00 to 125.00 mm

View More Details

DeFelsko UTGCX3-G PosiTector UTG CX3 Advanced Ultrasonic Thickness Gage with Xtr...

- DeFelsko UTGCX3-G PosiTector UTG CX3 Standard Ultrasonic Thickness Gage with PRBUTGCX-C Xtreme Corrosion Probe, 5 MHz Dual Element

- Measuring Range: 0.040" - 5.000" (1.00 - 125 mm)

View More Details

DeFelsko UTGCLF3-G PosiTector UTG CLF3 Advanced Ultrasonic Thickness Gage with L...

- DeFelsko UTGCLF3-G PosiTector UTG CLF3 Advanced Ultrasonic Thickness Gage with Low Frequency Probe, 2.25 MHz Dual Element

- Measuring Range: 0.080" to 5.000" - 2.00 to 125.00 mm

View More Details

DeFelsko UTGM3-G PosiTector UTG M3 Advanced Ultrasonic Thickness Gage with Multi...

- DeFelsko UTGM3-G PosiTector UTG M3 Advanced Ultrasonic Thickness Gage with PRBUTGM-C Multiple Echo Probe, 5 MHz Contact

- Measuring Range Multiplo Echo: 0.100" to 2.500" (2.50 to 60.00 mm)

- Thru-Paint Capability (Multiple Echo): Measures the metal thickness of a painted structure without having to remove the coating.

View More Details

DeFelsko UTGP3-G PosiTector UTG P3 Advanced Ultrasonic Thickness Gage with Preci...

- DeFelsko UTGP3-G PosiTector UTG P3 Advanced Ultrasonic Thickness Gage with Precision Probe, 15 MHz Single Element Delay Line

- Steel Measuring Range: 0.008" to 0.475" - 0.2 to 12.0 mm | Plastic Measuring Range: 0.005" to 0.175" - 0.125 to 4.500 mm

View More Details

Links

Contact US

ABQ Industrial21 Waterway Avenue

Suite 300

The Woodlands, TX 77380

U.S.A.

Tel: 1-281-516-9292

Fax: 1-866-234-0451

E-Mail: info@abqindustrial.net

We Accept

LINKS

CONTACT US

ABQ Industrial21 Waterway Avenue

Suite 300

The Woodlands, TX 77380

U.S.A.

Tel: 1-281-516-9292

Fax: 1-866-234-0451

E-Mail: info@abqindustrial.net

WE ACCEPT