General Purpose Digital Tension Meter

10 Tension ranges available from 5.0 - 200 cN up to 0.6 - 60 daN

For use with ribbons, filaments, carbon strands, foils and similar flat materials

Stationary electronic tension sensor for measuring tensions of textile ribbons, films, foils, tows, rovings, fiber bunches and more.

- 10 Tension ranges available from 5.0 - 500 cN up to 0.5 - 50 daN

- Electronic tension meter for applications in textile and wire industry.

- Versatile applicable hand-held unit.

Kit Contents

- DTSB - Narrow Tape / Digital Hand-Held Tension Meter

- Four (4) AA batteries

- Accumulator

- AC adapter

- Certificate of compliance with the order 2.1 according EN 10204 free of charge

- Instruction manual

- Carrying case

Features

- Dual-flanged outer guide rollers with various widths, from 7 mm to 30 mm (single-flanged rollers optional)

- For certain tension ranges and materials, it is possible to supply roller widths of 41 mm. Inquire.

- Large, backlight LCD-display with 3 different displays: numeric, numeric with live load bar, numeric with graph (time-tension)

- Display automatically rotates in 90° steps (or can be locked in any desired position)

- Built-in Diameter Compensator System is used to adjust calibration curve for highest accuracy. Diameter is set with wheel and shown on display

- Automatic "Zero-Setting" in all measuring positions using built-in gravity sensor

- 4 Seperate Calibration Material memory locations for custom calibrations (can be performed by end-user and saved with alpha-numeric name)

- Storage of Min, Max and Last reading as well as Hi-Peak, Low-Peak, average and standard deviation

- High speed internal data sampling (8 kHz) for capture of accurate Min & Max Peaks

- User-set Min and Max alarms with indication on LCD if reading is out of limits

- User-adjustable DAMPING is used to minimize tension fluctuations

- User-Selectable units of measurement: cN, daN, g, kg, N, lb

- Setup parameters can be password protected so they are not accidentally changed by the user

- Re-chargeable Lithium Polymer battery lasts 40 hours (continuous use, approx)

- Rugged aluminium housing with rubberized handle provides a secure and comfortable grip

- NIST-Traceable Calibration Certification in optionally available

Specifications

| Accuracy | For PA from 5 % up to 100 % FS*: ± 0.5 % FS* ± 1 digit remaining tension range and other calibration materials: ±3 % full scale and ±1 digit |

| Memory for material curves | 1 for factory calibration plus 4 for customized calibrations |

| Measuring units | Tension: cN, daN, g, kg, N, lb (user-selected)

Thickness : mm, inch (user-selected) |

| Overrange | Approx. 10 % FS*, full scale, without accuracy guarantee |

| Overload protection | 100 % full scale |

| Measuring principle | Strain gauge bridge |

| Measuring roller deflection | Max. 0.2 mm |

| Signal processing | Digital, 16 bit A/D converter |

| Measuring frequency | Max. 1 kHz (1000 measurings/sec.), intern 8 kHz |

| Display | Graphic LCD, Backlit (user-set: on/off/auto) |

| 3 different displays | Numeric, Numeric with graph (time-tension), X-Y-diagram |

| Display update rate | Approx. 2 times per second |

| Memory | MIN, MAX, PEAK, AVG and LAST |

| Damping | User-adjustable electronic damping (averaging)

calculated by [X-Values OLD + Y-Values NEW] ÷ 9 |

| Cal. Adjustment | ± 10 steps in 1 % increment |

| Thickness compensation | Max. 2.5 mm (not available for all models) |

| Auto power off | Approx. 3 minutes of non-use |

| Temperature coefficient | Gain: less than ± 0.01 % FS* /°C

Zero point: less than ± 0.3 % FS* /°C |

| Temperature range | 10 - 45 °C |

| Air humidity | 85 % RH, max. |

| Power supply | Rechargeable Lithium Polymer Battery provides 40 hours of continuous operation, charging time approx. 3-1/2 hours includes AC-Adapter/Charger 100 – 240 V AC (with EU, USA, UK plug adapter) |

| Housing material | Die-cast aluminium |

| Weight, net (gross) | Up to DTS-50K approx. 875 g / 1550 g

DTS-60K-V1 approx. 1040 g / 2700 g |

Ranges

Notes

* Factory calibration material textile ribbon or film, depending on tension range and roller width

** Outer distance between outside guide rollers

***Lever no longer required for high capacity models

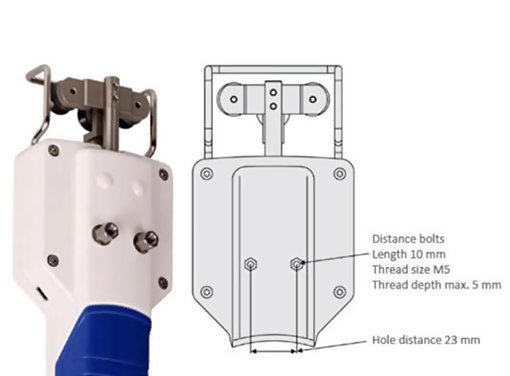

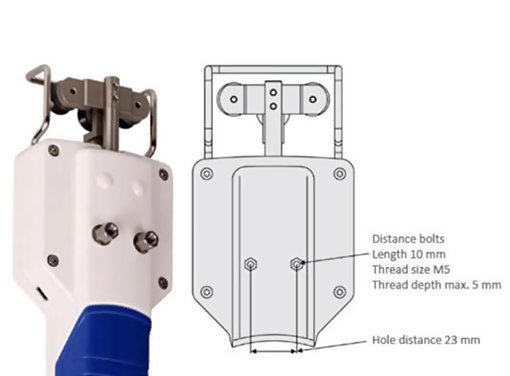

Roller Guide

Other roller materials (nickel-plated steel or plastic), as well as special coatings (Code CF – for carbon fibre, NAV optimized, Code KE – ceramic, Code AH – anti adhesive) are available on request.

Related Products

Downloads