Storage of 250,000 readings in up to 1,000 batches

Body Only

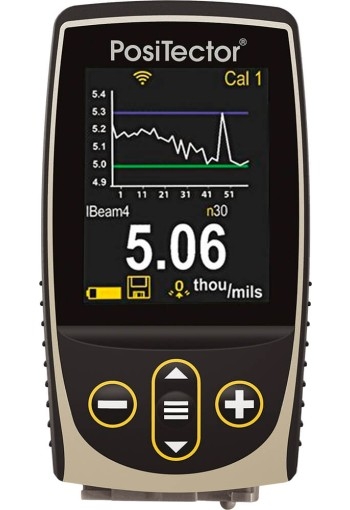

Manufacturer: DeFelsko

Warranty: One Year

PosiTector Gage Bodies can be used with all PosiTector probes.

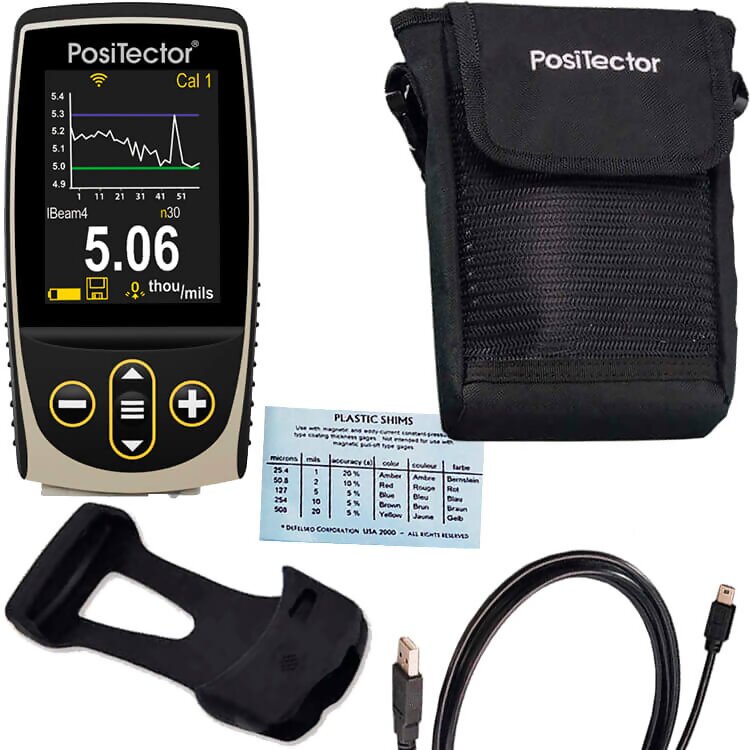

Kit Contents

- PosiTector Standard Gage Body BDYAVD-G

- Protective rubber holster with belt clip

- Wrist strap and protective lens shield

- 3 AAA alkaline batteries

- USB cable

- Nylon carrying case

- Two (2) year warranty

Features

- Storage of 250,000 readings in up to 1,000 batches and sub-batches

- Touchscreen keyboard quickly renaming batches, adding notes, and more

- WiFi technology wirelessly synchronizes with PosiSoft.net and downloads software updates

- Bluetooth 4.0 Technology for data transfer to a mobile device running the PosiTector App or optional portable printer. BLE API available for integration into third-party software.

- Store thickness, profile, environmental, wall thickness, hardness and salt contamination measurements in individual batches

DeFelsko PosiTector Gage Bodies: Feature Comparison Chart

Feature Comparison Chart For all DeFelsko PosiTector: |

Standard |

Advanced |

| NEW Larger 2.8" impact resistant color touchscreen with redesigned keypad for quick menu navigation |  |  |

| NEW On-gage help explains menu items at the touch of a button |  |  |

| NEW Weatherproof, dustproof, and water-resistant - IP65-rated enclosure |  |  |

| NEW Ergonomic design with durable rubberized grip |  |  |

| NEW Auto rotating display with Flip Lock |  |  |

| NEW Screen Capture - save 100 screen images for record keeping and review |  |  |

| NEW Up to 30% longer battery life |  |  |

| Reading Storage Capacity | 1,000 per probe | 250,000 in up to 1,000 batches |

| NEW Touchscreen keyboard for quickly renaming batches, adding notes, and more | --- |  |

| WiFi technology wirelessly synchronizes with PosiSoft.net and downloads software updates | --- |  |

| Bluetooth 4.0 Technology for data transfer to a mobile device running the PosiTector App or optional portable printer. BLE API available for integration into third-party software | --- |  |

| Integrate with third-party software, drones, ROVs, PLCs, and robotic devices using several industry-standard communication protocols | --- |  |

| DeFelsko PosiTector 6000 Only: |  |

| Extended cables available (up to 75 m/250 ft) for underwater or remote measuring |  |  |

| NEW Instant-on feature quickly powers up the gage if recently powered down |  |  |

| Live graphing of measurement data | --- |  |

| NEW Prompted Batch Mode - create pre-defined batches with on-screen text and image prompts for each reading | --- |  |

3 Scan Modes - increase measurement speed to 180+ readings per minute:

Normal – take continuous readings without lifting the probe

Statistics – take continuous readings and record average, standard deviation, min/max thickness and number of readings while scanning

Limited Count Average – take continuous readings up to a user-specified count. The gage displays and records the average of the readings. | --- |  |

| Multiple stored calibration adjustments for measuring on a variety of substrate conditions | --- |  |

| NEW SSPC-PA 2, ISO 19840, and IMO PSPC 90/10 modes help users comply with standards by prompting for min/max specifications, displaying the necessary readings, and automatically calculating statistics with a pass/fail result | --- |  |

| DeFelsko PosiTector 200 Only: |  |

| Measure the total thickness of a coating system or up to 3 individual layer thicknesses in a multi-layer system | --- |  |

| Graphics mode with screen capture for detailed analysis of the coating system | --- |  |

| NEW Prompted Batch Mode - create pre-defined batches with on-screen text and image prompts for each reading | --- |  |

| Live graphing of measurement data | --- |  |

| DeFelsko PosiTector SST Only: |  |

| Easy 1-2-3 gage interface guides users through the Bresle test method |  |  |

| DeFelsko PosiTector SPG Only: |  |

| NEW Instant-on feature quickly powers up the gage if recently powered down |  |  |

| SmartBatch™ allows entry of user-defined parameters and criteria to for quick statistical analysis comply with standards such as ASTM D4417 and SSPC PA-17 | --- |  |

| Live graphing of measurement data | --- |  |

| DeFelsko PosiTector DPM Only: |  |

| NEW Instant-on feature quickly powers up the gage if recently powered down |  |  |

| Enhanced Auto Log mode turns the gage off between readings for up to 8 months of battery life. Each reading can be uploaded to PosiSoft.net or an FTP server using WiFi. Automatically group readings into batches at daily, weekly, or monthly intervals. | --- |  |

| User defined limits for all parameters - visible and audible warnings. Receive email alerts when connected to WiFi. | --- |  |

| Trend Charts graph readings in real-time | --- |  |

| Wet bulb temperature can be displayed and recorded | --- |  |

| DeFelsko PosiTector UTG Only: |  |

| Pre-programmed velocities - simply select from a list of common materials or enter your own with ease |  |  |

| A-Scan with adjustable Gain and screen capture. UTG M and UTG P probes include dual cursors to measure the distance between echoes | --- |  |

| B-Scan - displays a cross sectional profile of the test material | --- |  |

| DeFelsko PosiTector RTR-H Only: |  |

| Produces a more accurate peak-to-valley height measurement. See linearized peak height (HL) |  |  |

| DeFelsko PosiTector RTR-3D Only: |  |

| NEW Ergonomic design with durable rubberized grip |  |  |

| Live graphing of measurement data | --- |  |

| Download high resolution Surface Data Files (.SDF) for analysis in the included PosiSoft or third-party software | --- |  |

| Generates two dimensional (2D) and three dimensional (3D) thumbnail images. Ideal for inclusion into reports and confirming consistent blasting results | --- |  |

| DeFelsko PosiTector IRT Only: |  |

| NEW Instant-on feature quickly powers up the gage if recently powered down |  |  |

| Trend Charts graph readings in real-time | --- |  |

| Store thickness, profile, environmental salt contamination, hardness, and wall thickness measurements in individual batches | --- |  |

| DeFelsko PosiTector SHD Only: |  |

| NEW Instant-on feature quickly powers up the gage if recently powered down |  |  |

| Auto Sub-Batch - automatically create sub-batches after the required number of readings are taken | --- |  |

| Live graphing of measurement data | --- |  |

| Store thickness, profile, environmental, wall thickness, and hardness measurements in individual batches | --- |  |

| DeFelsko PosiTector BHI Only: |  |

| NEW Instant-on feature quickly powers up the gage if recently powered down |  |  |

| Auto Sub-Batch - automatically create sub-batches after the required number of readings are taken | --- |  |

| Live graphing of measurement data | --- |  |

| Store thickness, profile, environmental, wall thickness, and hardness measurements in individual batches | --- |  |

For use with the: DeFelsko PosiTector 6000, DeFelsko PosiTector 200, DeFelsko PosiTector SPG, DeFelsko PosiTector RTR H, DeFelsko PosiTector RTR 3D, DeFelsko PosiTector DPM, DeFelsko PosiTector IRT, DeFelsko PosiTector SST , DeFelsko PosiTector UTG, DeFelsko PosiTector SHD, DeFelsko PosiTector BHI

Downloads

F.A.Q.

Is the DeFelsko PosiTector 6000 calibrated at the factory?

DeFelsko PosiTector 6000 instruments arrive fully calibrated and include a Long-Form Certificate of Calibration traceable to NIST or PTB. The Certificate of Calibration documents actual readings taken by your instrument at our calibration laboratory, on standards traceable to a national metrology institute. Beware of ‘Certificates’ or ‘Certificates of Conformance’ offered by competitors. These typically do not include actual instrument readings, and are often insufficient to meet common quality requirements.

Does the DeFelsko PosiTector 6000 need to be ‘calibrated’ or ‘adjusted prior’ prior to use? Do I need to perform a two-point adjustment prior to measuring?

The innovative probe technology and factory calibration in the DeFelsko PosiTector 6000 means that it arrives ready-to-measure - usually there is no need to perform a two-point calibration adjustment. Ruby or alumina probe tips on standard probe models eliminate wear, meaning that the factory calibration is maintained throughout the lifetime of the probe. Whether out of the box or after years of use, DeFelsko PosiTector 6000 will continue to provide accurate results.For highest confidence and best measurement accuracy, observe our “golden rule” - simply check ZERO (or the known thickness of a shim) on the uncoated part, adjust if necessary, and then measure the coated part. This ensures that the probe is properly adjusted for substrate characteristics including mass, metallurgy, curvature, temperature and roughness.

Do your instruments require any formal training for use? Do you offer ‘demo’ models?

No. Our instruments are designed for simple operation, feature easy-to-use menus, both full and quick instruction manuals, and helpful videos. In lieu of demonstration models, we provide unlimited technical support via telephone and/or email, and a limited 30-day money back guarantee.

How often should the DeFelsko PosiTector 6000 be recalibrated?

DeFelsko PosiTector 6000 probes include a Certificate of Calibration with no expiry or end date. They have no shelf life, therefore the length of time in the field is not a good indicator for recalibration intervals. Many organizations with quality programs and recertification programs require annual recalibrations, and this is a good starting point for most users. DeFelsko recommends that customers establish calibration intervals based upon their own experience and work environment. Based on our product knowledge, data and customer feedback, a one year calibration interval from the date the instrument was placed in service is a good starting point.

What can the DeFelsko PosiTector 6000 measure?

DeFelsko PosiTector 6000 paint thickness probes have different capabilities depending on the model.

- ‘Ferrous’ model probes (order code beginning in ‘F’

ex. FS1) can measure non-magnetic coatings applied to ferrous (magnetic) metals, typically carbon steel.

- ‘Non-ferrous’ model probes (order code beginning in ‘N’ ex. NRS3) can measure non-conductive coatings applied to non-ferrous metals.

- ‘Combination model probes (order code beginning in ‘FN’ ex. FNTS1) can measure non-magnetic coatings applied to ferrous (magnetic) metals, AND non-conductive coatings applied to non-ferrous metals

Is the DeFelsko PosiTector 6000 affected by the surface roughness (profile) of the metal substrate below the coating?

All coating thickness gages are influenced to some degree by substrate roughness, as shown in the below image. It is generally accepted that coating thickness should be measured from the highest ‘peaks’ in the rough surface thus ensuring they are covered by the protective coating. However, coating thickness gages will instead measure the coating thickness from the ‘effective magnetic plane, which is located somewhere between the highest peaks and deepest valleys of the profile.

SSPC-PA 2 proposes several solutions depending upon the instrument type and the particular situation. Similar methods are suggested by ASTM D7091 and ISO 19840.

One option is to verify the gage reads zero on the uncoated steel substrate, and adjust to zero if necessary. This is a popular solution when the metal surface is relatively smooth.

Since it is difficult to ensure that the probe tip is sitting on the highest peaks of the surface profile, another option is to place a plastic shim of a known thickness that is close to the expected thickness of the applied coating between the probe and substrate and adjust to the stated thickness of the shim- referred to as a 1-point adjustment. The plastic shim sits on the peaks of the surface profile over a greater area than the probe tip, ensuring that the adjustment is being taken ‘over the peaks’. This best simulates a coating covering the peaks of the surface profile.

Can the DeFelsko PosiTector 6000 measure coatings on stainless steel?

"Stainless steel" is a term used to generally categorize a wide variety of corrosion and heat-resistant alloys. In specific terms of metallurgy, a “stainless steel” is any iron-based alloy containing a minimum of 10.5% chromium content by mass. Some stainless steel alloys have a relatively low magnetic response (often called “partially/weakly magnetic”). Others have no magnetic response whatsoever, and some possess a ferromagnetic response similar to carbon steel.The DeFelsko PosiTector 6000 is uniquely able to measure partially magnetic stainless steel alloys, an application that is challenging for many competitive instruments. DeFelsko PosiTector 6000 FN (combination ferrous/non-ferrous) probe models can often measure consistently on partially magnetic substrates with a simple Zero adjustment. For more challenging applications, the “N-Lock” measurement mode permits accurate measurement of non-conductive coatings applied to partially magnetic substrates.

Can the DeFelsko PosiTector 6000 measure coatings on hot surfaces?

The DeFelsko PosiTector 6000 FXS and FHXS Xtreme probes are ideal for measuring coating thickness on hot and/or rough surfaces (250°C, 500°F maximum). All DeFelsko PosiTector 6000 probe are capable of measuring on hot surfaces. Standard probe models can operate at environments up to 50˚C (120˚F). However, if the probe is lifted clear of the surface as soon as a reading is taken and is allowed to cool, measurements can be taken at higher temperatures. Simply ensure that the probe remains at a temperature of less than 50˚C (120˚F), and cool enough to handle with an unprotected hand.

What is the minimum part size required to take a reading?

To ensure a part’s dimensions are suitable for a DeFelsko PosiTector 6000 probe, simply check ZERO on the uncoated part and adjust if necessary. Verify accuracy by measuring a plastic shim placed on the uncoated part. If the measurement is within the combined tolerances of the shim and probe, the probe is suitable for measuring the coated part.

Can the DeFelsko PosiTector 6000 be used underwater?

While the PosiTector gage body and probe connector are not suitable for immersion in water, DeFelsko PosiTector 6000 regular cabled probes are hermetically sealed and ideal for underwater use. Extended cables are available (up to 75 m/250 ft) for underwater or remote measuring.

Is the DeFelsko PosiTector 6000 intrinsically safe?

While the DeFelsko PosiTector 6000 is not designed as an intrinsically safe device, our PosiTest mechanical gages are ideal for measuring coating thickness in hazardous operating environments.

Can the DeFelsko PosiTector 6000 measure nickel on steel?

Yes, but it depends upon the particular type of nickel coating that has been applied to the steel.

When nickel plating is deposited by a process of electrolysis (employing an electric current in the nickel bath), the resultant coating – commonly called “e-nickel” – is always conductive and magnetic to some degree and cannot be accurately measured by our gages when applied to ferrous or non-ferrous metals.

Electroless nickel coatings are deposited by an autocatalytic process which does not involve the addition of an electric current. If the nickel bath in this process contains a minimum concentration of ~8% phosphorus, the resulting nickel plating is effectively non-magnetic and its thickness can be accurately measured on ferrous steel with a magnetic principle coating thickness gage such as a DeFelsko PosiTector 6000 F model.

What is the measurement range of the DeFelsko PosiTector 6000?

The coating thickness measurement range of the DeFelsko PosiTector 6000 is dependent on which interchangeable probe is attached. DeFelsko PosiTector 6000 probes are available for measuring a wide variety of coating thickness applications.For example, the DeFelsko PosiTector 6000 FN probe can measure coating thicknesses up to 1500 um (60 mils), while the DeFelsko PosiTector 6000 FNGS probe measures coatings up to 63.5 mm (2.5 inches) thick. No matter your application, DeFelsko likely has a measuring solution to satisfy your requirement.

What is a mil?

A mil, also known as a Thou, is equal to 1 one-thousandth of an inch (25.4 microns).

What is a micron?

A micron, sometimes called a micrometer, is equal to one-millionth of a meter or one-thousandth of a millimeter (~0.000039").