PosiTector SPG Surface Profile Gauge Instruction Manual

Table of Contents |

|

Introduction

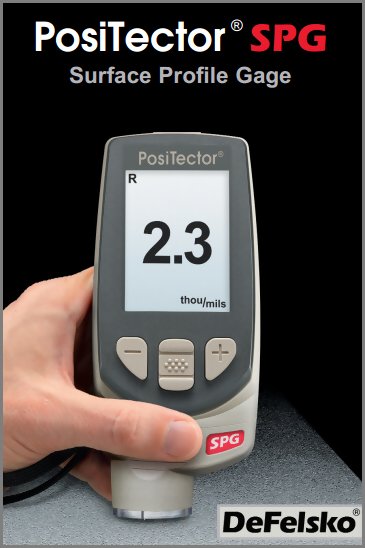

The PosiTector Surface Profile Gage (SPG) is a hand-held electronic instrument that measures the peak-to-valley height of the surface profile of abrasive blast cleaned surfaces. It consists of a body (Standard or Advanced) and probe.

PosiTector SPG Kit Content

|

|

![]()

Protective Cap ![]()

|

PosiTector SPG models are shipped with a protective plastic cap over the probe. Remove this cap prior to use. Replace it when the instrument is not in use to protect the probe. Wrist Strap: We recommend attaching and wearing the supplied wrist strap. |

![]() Plastic Lens Shield

Plastic Lens Shield![]()

The LCD is covered with a thin plastic film for protection against fingerprints and other marks during shipment. This film, while usually removed before using the instrument, can be left in place to protect against paint overspray. Replacements can be purchased.

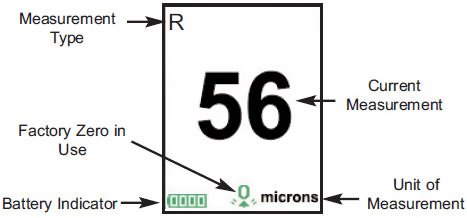

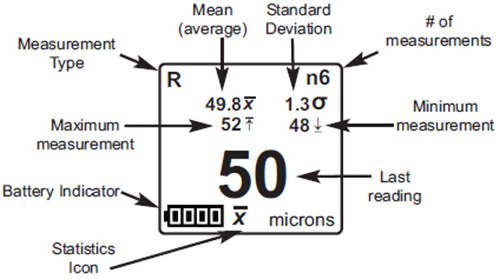

Typical Screen

The PosiTector SPG powers-up when the center navigation button is pressed. To preserve battery life, it powers-down after approximately 5 minutes of no activity. All settings are retained.

- Remove the protective plastic cap from probe.

- Power-up Gage by pressing the center navigation

button.

button. - Place the included glass zero plate onto a stable, flat surface. Take a measurement on the plate with the PosiTector SPG. If the average of several readings is greater than ± 5 µm (0.2 mil), zero the instrument.

- Place the probe FLAT on the surface to be measured such that the tip of the probe reaches into the bottom of a profile valley. HOLD STEADY. The Gage will BEEP twice and display the measurement.

- Lift the probe from the surface between measurements.

![]() Certification

Certification![]()

All probes include a Certificate of Calibration. For organizations with re-certification requirements, instruments may be returned at regular intervals for calibration. DeFelsko recommends that customers establish calibration intervals based upon their own experience and work environment. Based on our product knowledge, data and customer feedback, a one year calibration interval from either the date of calibration, date of purchase, or date of receipt is a typical starting point. Written calibration procedures are available from DeFelsko Corporation at no charge.

![]() Why is Measurement Important?

Why is Measurement Important?![]()

Steel is often abrasive blast cleaned or otherwise roughened prior to painting. The peak-to-valley height of the resultant surface profile is an important factor in the performance of applied protective coatings.

Low profile may reduce coating bond strength (adhesion). Too high and the peaks may receive insufficient coverage and possibly rust prematurely. The costly application of more coating may be required if the profile is too high.

For these reasons, surface profile should be measured prior to coating application to ensure that it meets contract specifications.

|

The PosiTector SPG consists of a body and a probe. See Info to find your body and probe type. More probe information is available at www.defelsko.com/SPG. To disconnect a probe from a body, power-down the instrument and pull the plastic probe connector horizontally (in the direction of the arrow) away from the body. Reverse these steps to attach a new probe. When powered-up the PosiTector automatically determines what type of probe is attached and does a self-check. The supplied probe tip has a 60° angle to comply with most test standards including ASTM D 4417 B. An optional 30° angle tip with replacement tool is available for special applications or to comply with Australian Standard AS 3894.5. |

A replacement tool is included with the purchase of either the 60° or 30° angle tips. Insert the two legs of the replacement tool into the probe tip and turn counter clockwise to remove the tip. Insert the new tip and tighten clockwise. Do not over tighten. Since the factory zero setting may not always be precise after a probe tip exchange, the gage should be checked on the included glass plate and zeroed if necessary.

PosiTector body accepts all 200, 6000, SPG, RTR, DPM and UTG probes.

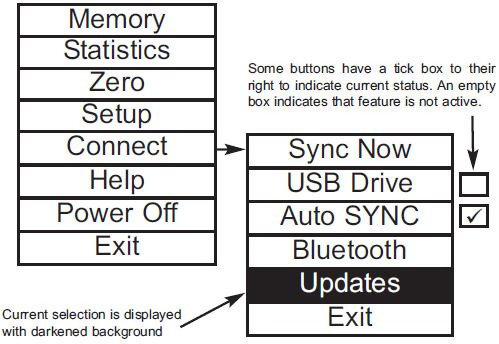

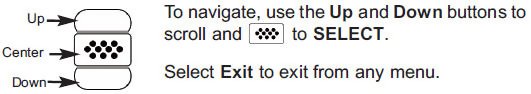

Instrument functions are menu controlled. To access the Menu, power-up the instrument, then press the center navigation button.

Below is a sample menu for a PosiTector SPG Advanced Model:

![]() Navigation Button

Navigation Button ![]()

![]() Calibration & Verification of Accuracy

Calibration & Verification of Accuracy![]()

![]() Calibration

Calibration![]()

Instrument calibration is typically done by the manufacturer or qualified lab. All probes include a Certificate of Calibration showing traceability to a national standard. For organizations with re-certification requirements, the PosiTector SPG may be returned at regular intervals for calibration.

DeFelsko recommends that our customers establish Gage calibration intervals based upon their own experience and work environment. Based on our product knowledge, data and customer feedback, a one year calibration interval from either the date of calibration, date of purchase, or date of receipt is a typical starting point.

Written Calibration Procedures are available online at no charge.

![]() Verification of Accuracy

Verification of Accuracy![]()

Instrument accuracy is verified using the included metal shim and glass zero plate.

Place the plate onto a stable, flat surface. Take several measurements. If the average is greater than ±5 µm (0.2 mil), zero the instrument.

Next, place the metal shim over the glass plate and measure ensuring the probe needle touches the glass plate in the area between the shim’s “legs”. The average of several measurements should be within the combined tolerances of both the shim and the gage (±10%). For example, measuring a 75 µm (3 mil) shim should result in values between 67.5 µm (2.7 mils) and 82.5 µm (3.3 mils).

To guard against measuring with an improperly adjusted Gage, verify the Gage at the beginning and the end of each work shift. During the work shift, if the Gage is dropped or suspected of giving erroneous readings, its accuracy should be re-verified.

In the event of physical damage, wear, high usage, or after an established calibration interval, the gage should be returned to the manufacturer for repair or calibration.

![]() Zeroing the Instrument

Zero

Zeroing the Instrument

Zero![]()

The PosiTector SPG has only one adjustment point at zero. The zero point can be set using one of two methods. Both methods are found under the Zero menu option.

Glass Plate Zero: Setting the instrument to zero on the glass plate is the preferred zero adjustment method:

- Select Zero from the menu.

- Press the (+) button to select the number of readings to be used to obtain an average, typically 3.

- Repeatedly measure the glass plate. After the last measurement the gage will calculate a Zero which represents the average of all the Zero readings taken.

Factory Zero: If a glass plate or suitable smooth, hard surface is not available, the factory zero setting can be restored:

- Select Zero from the menu.

- Press the down button to select “Reset” and press the center navigation

button. The factory calibration icon

button. The factory calibration icon will appear on the LCD.

will appear on the LCD.

NOTE:

- The factory zero setting is restored during a RESET.

- The factory zero setting may not always be precise, particularly after a probe tip exchange. For best accuracy, the gage should be zeroed on the included glass plate.

![]() Reset

Reset![]()

Reset (soft reset) restores factory settings and returns the instrument to a known condition. The following occurs:

- All batches, stored measurements, images, and batch names are erased.

- The zero adjustment is returned to the factory setting. Since this may not always be a precise zero, the gage should be checked on the glass plate.

- Menu settings are returned to the following:

- Memory = OFF

- Hi Lo Alarm = OFF

- Statistics Mode = OFF

- Blue

- tooth = OFF

Perform a more thorough Hard Reset by powering down the instrument, waiting several seconds, then simultaneously holding both the center ![]() and (+) buttons until the Reset symbol

and (+) buttons until the Reset symbol ![]() appears. This returns the instrument to a known, “out-of-the-box” condition. It performs the same function as a menu Reset with addition of:

appears. This returns the instrument to a known, “out-of-the-box” condition. It performs the same function as a menu Reset with addition of:

- Bluetooth Pairing info is cleared.

- Menu settings are returned to the following:

- Units = microns

- Language = English

- Flip Display = Normal

- Battery Type = Alkaline

- Auto Sync = OFFBacklight = Normal

- White on Black = OFF

- Bluetooth Streaming = OFF

- USB Drive = ON

NOTES:

- Keep the gage away from metal during a Reset.

- Date and Time are not affected by either Reset.

Displays the model number & serial number, probe type & serial number, PosiSoft.net registration key, the amount of remaining memory for storage of readings, date and time, and software packages.

For security purposes, the registration key is required to add the instrument to your free PosiSoft.net account.

Flip Display: This option causes the display to read upside down. Ideal for use overhead with the resultant display conveniently pointed toward the operator.

White on Black (Advanced models only): Inverts the LCD display to white on a black background to provide better readability in some surroundings.

Backlight (Advanced models only): Selects display brightness (Sun, Normal or Night). All settings will dim slightly after a period of no activity to conserve battery life. Press the Down button to brighten the display.

Set Clock: All batches are date-stamped when created, and all readings are time-stamped (24 hour format) when stored into memory. It is therefore important to keep both the date and time current using this menu option. Use the Up and Down buttons to scroll, and the (-) and (+) buttons to adjust a value. The instrument’s data and time can also be viewed in Info.

Battery Type: Selects the type of batteries used in the instrument from a choice of “Alkaline”, “Lithium” or “NiMH” (Nickel-metal hydride rechargeable). If NiMH is selected, the instrument will trickle charge the batteries while connected via USB to a PC or optional AC charger. The battery state indicator icon is calibrated for the selected battery type. No damage will occur if the wrong battery type is selected.

NOTE: DeFelsko recommends the use of eneloop (NiMH) rechargeable batteries.

Units: Converts the display from inch to metric or vice versa. Stored measurements in memory are not converted.

NOTE: Switching units will turn off Statistics, HiLo Alarm, and closes Memory.

Language:

Converts displayed and printed words to the selected language.

Statistics ![]()

When selected, a ![]() icon and statistical summary will appear on the display.

icon and statistical summary will appear on the display.

Remove the last measurement by pressing the (-) button. Press (+) to clear statistics.

HiLo Alarm ![]()

Allows the Gage to visibly and audibly alert the user when measurements exceed user-specified limits.

When HiLo Alarm is selected, the current Lo setting is displayed. Adjust down (-) or up (+). Alternatively, measure a coating with a thickness close to the required value and make final adjustments with the buttons. Select NEXT to accept this value. The current Hi setting is now displayed. Follow the same procedure to adjust the Hi setting.

The ![]() icon will appear on the display.

icon will appear on the display.

Measurements will be compared to your defined HiLo limits. The Gage beeps if results are within those limits. A single low tone will sound if the reading is below the Lo limit, and a high tone if it is above the Hi limit. Press (+) to clear HiLo readings.

Clear

Clears all on-screen Statistics and HiLo tabulations.

The PosiTector SPG can record readings in memory for printing to the optional Bluetooth wireless printer, transfer to a computer or synchronizing with PosiSoft.net. Readings are time-stamped as they are stored.

Standard models store up to 250 readings in one batch. The following appears within the Memory menu:

On: turns memory on and begins recording

Off: stops recording (stored readings remain in memory)

Clear: removes all readings from memory

View: lists group statistics and all stored readings on the display. It will begin by showing statistics based on all readings in memory. Use the Up and Down buttons to scroll through all readings. Press ![]() to exit.

to exit.

Advanced models store 100,000 readings in up to 1,000 batches (groups). The following appears within the Memory menu:

New Batch

Closes any currently opened batch and creates a new batch name using the lowest available number. For example, if only Batch 1 and Batch 3 exist, then Batch 2 would be created and made the current batch. The ![]() icon appears and basic statistics are displayed. Each measurement will be displayed and stored into this new batch. On screen statistics are immediately updated with each measurement. New batch names are date stamped at the time they are created.

icon appears and basic statistics are displayed. Each measurement will be displayed and stored into this new batch. On screen statistics are immediately updated with each measurement. New batch names are date stamped at the time they are created.

Shortcut: When a batch is open, press (+) to create a new batch

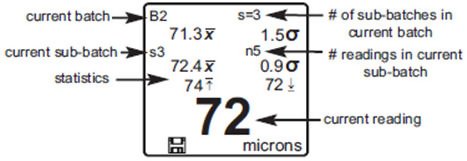

New Sub-Batch (appears only if a batch is currently open)

Creates a new sub-batch within the currently opened batch.

Shortcut: When a sub-batch is open, create a new sub-batch by pressing (+)

In the following example, B2s2 is a sub-batch of Batch 2. Subbatching allows the user to group related batches so that statistics can be accumulated for them. Batch 2 contains the statistics for B2s1 and B2s2.

SmartBatch ![]()

The PosiTector SPG measures the depth of a single valley in relation to the height of the surrounding peaks using a pointed, cone-shaped probe.

A single depth measurement generally does not adequately characterize the surface profile of an abrasive blast cleaned surface. Repeated gage readings often differ due to surface irregularities even at points close together. Therefore most organizations and contract specifications require multiple measurements be taken and analyzed to produce a final result that better characterizes the surface.

The Smart Batch menu option sets-up the PosiTector SPG to comply with the statistical approaches defined in various standards and test methods published by organizations such as ASTM, SSPC, ISO, IMO, US Navy, SANS and AS.

For instructions on how to use the Smart Batch™ feature

Open

Selects a previously created batch or sub-batch name to open and make current. If it contains measurements, on-screen statistics will immediately reflect values calculated from this batch. The calibration setting (i.e. Cal 2) associated with this batch is also opened.

NOTE: A solid triangle ![]() is displayed to the right of the batch name when sub-batches are present. Press

is displayed to the right of the batch name when sub-batches are present. Press ![]() to view sub-batches. This also applies to the Delete, View and Print options.

to view sub-batches. This also applies to the Delete, View and Print options.

Close: Stops the recording process, closes the current batch, and removes batch information from the display.

Delete: Removes a batch or sub-batch completely from memory. The name is deleted and all measurements are erased. Sub-batches can be deleted individually. To delete all related sub-batches, simply delete the top-level batch.

View:

Scroll using the Up or Down buttons through information, statistical summary, and a list of each reading in the currently opened batch. Press ![]() to exit.

to exit.

Annotate (Advanced models only): Create meaningful batch names and enter notes directly on the instrument using a familiar onscreen QWERTY keyboard. Use the Gages navigation and (-)(+) buttons to enter annotations. Annotations can be synchronized with PosiSoft.net and are included in USB Mass Storage reports.

Print: Sends a statistical summary and individual measurements to the optional Bluetooth wireless printer.

NOTE: To cancel printing, press and hold the (-) and (+) buttons simultaneously

Display (appears only if a batch is currently open): The following user selectable display options are available:

- Chart: A real-time x-y chart of batch or sub-batch readings.

- Image: An image uploaded (synchronized) from PosiSoft.net.

- Notes: Instructions or notes uploaded from PosiSoft.net.

- None: default screen showing statistics information when a batch is open.

- Shortcut: When a batch is open, press Up to scroll through the above display options.

NOTES: Remove the last reading from the current open batch by pressing (-).

Calibration adjustments cannot be made if any measurements were taken with that setting and stored into a batch.

If memory is ON while continuous measurements are being taken, only the last value on the display (when the probe is lifted) is stored into memory. Scan Mode stores all measurements into memory.

Each batch can contain a maximum of 10,000 readings.

The PosiTector can be connected to a computer using the included USB cable or Bluetooth wireless technology.. The USB connection has the following capabilities:

|

The USB port resides on the top of the instrument, behind a rubber flap. |

![]() PosiSoft.net

PosiSoft.net![]()

To enhance the operation of their Gage, all PosiTector users have access to the features provided by PosiSoft.net. It is a free web- based application offering secure centralized management of thickness readings.

After (1) a user account has been created, (2) a gage has been registered, and (3) the PosiTector Desktop Manager is downloaded and installed onto a Windows PC, synchronization of measurement data can be performed either manually or automatically whenever the PosiTector is connected to a web enabled PC by either USB cable or Bluetooth wireless technology. Gage measurements stored in memory are uploaded; images and batch notes are downloaded.

Uploaded data can be manipulated using a standard internet web browser from any location in the world - job site or head office. Reports and graphs with annotations and corporate logo can be generated. Data can be exported to XML or CSV comma delimited text files.

Measurement data can be shared with authorized users via a secure login from any computer and most web enabled devices including smart phones.

PosiTector Desktop Manager (PDM) is a small Windows based application which allows automatic two-way communication (synchronization) between the Gage and PosiSoft.net (internet connection required). When installed, PDM runs as a start-up application and resides in the Windows notification area (system tray) of a PC. PDM is available as a free download within your PosiSoft.net account.

Register your Gage on PosiSoft.net to take full advantage of your gage’s capabilities. See www.PosiSoft.net

![]() Outputting Stored Readings

Outputting Stored Readings![]()

Stored readings can be accessed using one of the following:

USB mass storage - connect your PosiTector to a PC/Mac using the suppled USB cable to access and print stored readings and graphs. No software or internet connection required.

PosiSoft.net - a free web-based application offering secure centralized storage of thickness readings. Access your readings from any web connected device. (See www.PosiSoft.net and Sync Now)

Bluetooth Printer (sold separately) Stream readings as they are taken or print batch readings and statistics.

Legacy PosiSoft Support -Existing PosiSoft users can continue using the familiar legacy PosiSoft software to download readings. Upgrade your PosiSoft version at: www.DeFelsko.com/PosiSoft

![]() Connect Menu

Connect Menu ![]()

Synchronizing (Sync) is the process whereby PosiTector stored measurement data uploads to PosiSoft.net (from both Standard and Advanced models) while images and batch notes are downloaded to the instrument (Advanced model only). This transfer occurs when the instrument is connected via USB or Bluetooth Wireless Technology to a web-enabled PC running the PosiTector Desktop Manager. It can be triggered either manually (USB or Bluetooth) or automatically (USB only).

Sync Now: Immediately initiates synchronization with PosiSoft.net when connected (USB or Bluetooth) to an internet connected PC running PosiTector Desktop Manager.

Multiple gages can be synchronized simultaneously when connected using multiple connections (for example two gages connected via USB and one gage connected via Bluetooth).

Auto SYNC ![]() :

Allows the instrument to automatically synchronize with PosiSoft.net when initially connected (USB or Bluetooth) to an internet connected PC running PosiTector Desktop Manager.

:

Allows the instrument to automatically synchronize with PosiSoft.net when initially connected (USB or Bluetooth) to an internet connected PC running PosiTector Desktop Manager.

Additional measurements added to memory while connected are synchronized only when the USB cable is disconnected, then reconnected or when Connect > Sync Now is selected.

USB Drive ![]() :

Universal Serial Bus (USB) is a specification to establish communication between devices and a host controller (usually a personal computer). USB has effectively replaced a variety of interfaces such as serial and parallel ports.

:

Universal Serial Bus (USB) is a specification to establish communication between devices and a host controller (usually a personal computer). USB has effectively replaced a variety of interfaces such as serial and parallel ports.

The PosiTector uses a USB mass storage device class which provides a simple interface to retrieve data in a manner similar to USB flash drives, cameras or digital audio players.

When checked, any computer can view and synchronize readings stored in memory by navigating a virtual drive labeled “PosiTector” using the included USB cable.

A formatted HTML report is viewed by selecting the "index.html" file found in the root directory. Optionally, text ".txt" files located in each batch folder provide access to measurement values. Stored readings and graphs can be viewed or copied using universal PC/Mac web browsers or file explorers.

When your PosiTector is first connected to your Windows PC via a USB cable, an enumeration process is started that installs device drivers without re-booting your computer. You may see several pop-up windows in the taskbar at the bottom right of your screen. Wait for the entire process to be completed before proceeding.

NOTE: When connected power is supplied through the USB cable. The batteries are not used and the body will not automatically power down. If rechargeable (NiMH) batteries are installed, the instrument will trickle charge the batteries.

![]() Bluetooth (Advanced models only)

Bluetooth (Advanced models only) ![]()

![]()

PosiTector Advanced models have Bluetooth functionality to:

- Communicate with the PosiTector Desktop Manager (PDM) in lieu of a USB cable.

- Stream individual readings to a computer or Bluetooth wireless printer as they are taken.

- Print to the optional battery powered Bluetooth wireless printer.

On: Turns Bluetooth functionality On. When selected, the ![]() icon will appear on the display. To deactivate Bluetooth, select Off.

icon will appear on the display. To deactivate Bluetooth, select Off.

Pairing: The instrument and receiving device must be paired before stored or streamed readings can be transmitted. For pairing instructions, see www.defelsko.com/bluetooth

Info: Lists information about your current Bluetooth connection, including the currently paired device and MAC address.

Stream: When checked, the instrument will stream readings to the paired Bluetooth Device as they are taken. Readings can be streamed as they are taken to the optional Bluetooth printer or third-party computer software.

|

PosiTector Advanced models can output to the optional battery powered Bluetooth wireless printer one of two ways:

Begin by entering the Connect > Bluetooth menu. Turn Bluetooth ON and “Pair” the PosiTector to the printer. See: www.defelsko.com/bluetooth |

Streaming: In the Connect > Bluetooth menu, select the “Stream” tick box. All readings will now be simultaneously displayed on the LCD and sent to the printer.

Printing: In the Memory menu, select Print.

|

Allows wireless communication with devices such as tablets, smart phones and computers connected to your local wireless network or portable mobile hot spot. See www.defelsko.com/WiFi On/Off |

Access Point ![]() : Connect your smart device/computer to a PosiTector Advanced body wirelessly without the need for a separate network. Wirelessly import readings into PosiSoft 3.0 Desktop Software or access PosiSoft Mobile in the field or whenever a WiFi network is not available or out-of-range.

: Connect your smart device/computer to a PosiTector Advanced body wirelessly without the need for a separate network. Wirelessly import readings into PosiSoft 3.0 Desktop Software or access PosiSoft Mobile in the field or whenever a WiFi network is not available or out-of-range.

To enable, select Access Point from the Connect > WiFi menu. The Access Point icon ![]() will display in the upper left of the PosiTector display.

will display in the upper left of the PosiTector display.

- Securing your Access Point

- To ensure the PosiTector is only accessible to authorized devices, it is important that you enter a passphrase (password) for the Access Point. The default Passphrase is password.

- In the Connect > WiFi > Setup menu, select AP Passphrase.

- Press

button to display on-screen keyboard. Enter a Passphrase for the Access Point. The Passphrase will be required for all devices connecting to the PosiTectors Access Point.

button to display on-screen keyboard. Enter a Passphrase for the Access Point. The Passphrase will be required for all devices connecting to the PosiTectors Access Point. - The PosiTector is now visible to all WiFi enabled devices. Simply connect your devices WiFi to the new PosiTector Access point. All PosiTectors are uniquely identified by their respective gage body serial numbers.

- AP Channel - Default Channel: 6

- For most users the default channel will not have to be altered. If you are experiencing poor connection or are unable to connect, try another channel.

- In the Connect > WiFi > Setup menu, select AP Channel.

- Press the UP center navigation button to highlight the channel. Use the (-) or (+) buttons to change the channel. Press the DOWN navigation button and select OK. Press the

button.

button.

- Import readings into PosiSoft 3.0 Desktop Software

- From the PosiSoft 3.0 menu, select Import > From Gage. All connected gages will display their unique serial number. Measurement data will be displayed upon completion of the import.

- The time it takes for import will depend on the number of Batches and measurements present within the gage. Imports generally take no longer than a few seconds.

- Batches are not erased from the gages memory during import. They remain on the gage until they have been deleted by the user.

- For more information regarding PosiSoft 3.0: http://www.defelsko.com/posisoft/posisoft_software.htm

- Accessing your PosiTector PosiSoft Mobile

- For use on Apple iOS and Android devices:

- PosiSoft Mobile Manager apps exist for Apple iOS and Android users. Simply download the App from the Apple App Store or Google Play.

- Once your smart device/computer has been connected to the PosiTector Access Point, open the PosiSoft Mobile Manager app. Select your PosiTector from the list to open PosiSoft Mobile.

- For use with all WiFi enabled devices:

- Any WiFi enable device connected to the PosiTector Access Point can view the instrument’s built-in PosiSoft Mobile web interface. Using your device’s web browser, enter the IP address of your PosiTector to access the features of PosiSoft Mobile.

- In the Connect > WiFi menu, select Information to view the IP address associated with your PosiTector.

- Enter the displayed IP address into your devices web browser exactly as it appears. Example: 192.168.0.1:8080

- For more information regarding PosiSoft Mobile:http://www.defelsko.com/posisoft/posisoft_mobile.htm

Networks: The Gage will allow the user to add a new network and will automatically check for available local networks. Available networks detected by the Gage are listed on the screen along with any networks that the Gage has previously been connected to that are not currently within connection range.

Information: Gage displays information about the local WiFi network connection including:

- SSID: the network’s name

- State: displays if the Gage is connected to the network or not

- IP Address: the network’s IP Address. Users can enter this number into a web-browser of any WiFi enabled device that is connected to the same network in order to view the Gage’s synced batches through PosiSoft Mobile.

Setup: Allows user to setup a WiFi connection

- IP Settings: enter the IP information as follows IP Type (DHCP or Static), IP Address, Gateway, Netmask, DNS1, DNS2.

- Server Enable: enables a connection between the network and the Gage.

- Gage Name: enter a name for the Gage (up to 14 Characters).

- WiFi Reset: erases all WiFi settings.

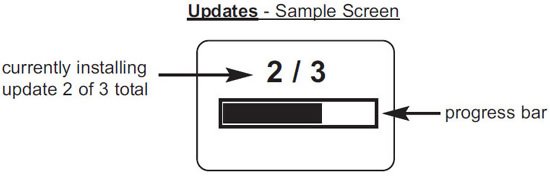

Determines if a software update is available for your instrument (must be connected to an internet connected PC with PosiTector Desktop Manager. If an update is available, a prompt will appear allowing the user to choose to perform the update at this time or not.

NOTE: Ensure that stored measurements are backed up to a PC or PosiSoft.net. The instrument may perform a hard Reset after completion of the update and ALL readings in memory would be erased.

![]() DO NOT unplug the gage during the update operation.

DO NOT unplug the gage during the update operation.

![]() Replacement Probe Tips

Replacement Probe Tips![]()

Two replacement probe tips are available. The first replaces the supplied 60° angle tip that complies with most test standards including ASTM D 4417 B. The second is a 30° angle tip for special applications or to comply with Australian Standard AS 3894.5. A replacement tool is included with both.

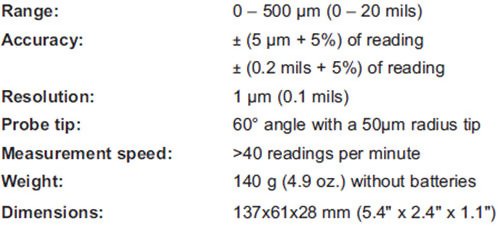

Operating range: +32° to +120°F (0 to +50°C)

The PosiTector SPG compensates automatically for temperature. Allow a few minutes for the probe to reach ambient temperature before measuring.

Discard the first measurement taken in a notably different temperature condition. When measuring surfaces much hotter or colder than ambient, lift the probe at least 6 inches (15cm) and allow 1 second off the surface between measurements.

![]() Power Supply / Battery Indicator

Power Supply / Battery Indicator![]()

Power Source: 3 AAA alkaline, Lithium or optional Nickel-metal hydride (NiMH) rechargeable batteries. For best battery indicator results, ensure the appropriate Battery Type is selected in the Setup > Battery Type menu.

The battery indicator ![]() displays a full bar with fresh alkaline or fully charged batteries installed. As the batteries weaken, the bar will be reduced. When the battery symbol is low

displays a full bar with fresh alkaline or fully charged batteries installed. As the batteries weaken, the bar will be reduced. When the battery symbol is low ![]() the instrument can still be used, but the batteries should be changed or recharged at the earliest opportunity. The instrument will turn off automatically when batteries are very low, preceded by a Low Battery Warning on the display.

the instrument can still be used, but the batteries should be changed or recharged at the earliest opportunity. The instrument will turn off automatically when batteries are very low, preceded by a Low Battery Warning on the display.

![]() To retain all user settings and stored memory readings, only replace the batteries after the instrument has powered-down. Battery performance decreases at low temperatures.

To retain all user settings and stored memory readings, only replace the batteries after the instrument has powered-down. Battery performance decreases at low temperatures.

Rechargeable Batteries (available option): DeFelsko recommends the use of eneloop (NiMH) rechargeable batteries. They combine the advantages of rechargeable batteries and disposable (Alkaline) batteries. They discharge very slowly and can be stored for long periods without having self discharge concerns. (See www.eneloop.info)

The PosiTector does not contain any user-serviceable components. Before returning the instrument for service:

- Install new or newly recharged batteries in the proper alignment as shown within battery compartment.

- Examine the probe tip for dirt or damage. The probe tip should move up and down freely. The metal plate surrounding the probe tip should be smooth and free from burrs and foreign material.

- Perform a Hard Reset.

- Place the metal shim over the glass plate and attempt a measurement.

If you must return the instrument for service, please fill out and include the service form located at www.defelsko.com/support with the instrument.

Most conditions can be cleared with a Hard Reset (see pg. 9). If not, visit our Service & Support page for information on sending your instrument to us for a no charge evaluation.

See: http://www.defelsko.com/service

- Thickness readings are inconsistent:

- Probe tip may be damaged, scratched or worn

- Gage will not print to the Bluetooth wireless printer:

- Ensure the gage has been paired for use with the printer and the Gage menu option Connect > Bluetooth > Stream box is ticked.

- Check printer batteries. Switch it off and then on again.

![]() Limited Warranty, Sole Remedy and Limited Liability

Limited Warranty, Sole Remedy and Limited Liability![]()

DeFelsko's sole warranty, remedy, and liability are the express limited warranty, remedy, and limited liability that are set forth on its website:www.defelsko.com/terms