DeFelsko PosiTector GLS Gloss Meter - Measuring Gloss

Measuring Gloss with the PosiTector GLS Gloss Meter

Consumers love gloss - this can be seen in almost every industry from automotive, to electronics, to baby toys. No matter the industry, gloss tends to be associated with luxury and wealth. Studies suggest that humans’ innate love for glossiness could be based on the biological need for water: the glossier an object, the more likely to ‘quench thirst’.

From an industry standpoint, gloss can have a very specific purpose. By definition, gloss is an optical property that indicates how well a surface reflects light in a specular (mirror-like) direction - or, how lustrous or shiny an object appears. While many industries prefer a glossier finish, some require a more matte finish.

![]() Why Measure Gloss?

Why Measure Gloss?![]()

| Measuring gloss while a product is being manufactured can improve the production process by identifying process issues, maximizing consistency, reducing waste, and improving overall quality. Surface texture, coating properties, and paint application can all have an effect on a coating’s appearance. While it’s easy for the human eye to detect large differences in gloss, like comparing a matte finish on a military asset to a glossy red sports car, smaller differences in gloss can be harder to see - but can still have a big impact on process control. |

![]() What is Reflectance?

What is Reflectance?![]()

| When light hits a surface, some of it is absorbed, and some is reflected. The reflected light is responsible for how the object is perceived. The nature of the reflection is generally related to the surface finish of the object. On a smooth, polished surface like a mirror, light is reflected opposite to the angle at which it arrives; this is referred to as ‘specular’ reflection. On a rough surface, light is reflected at all angles and a relatively small amount of light reflects at the specular angle. |

![]() What is Percent (%) Reflectance?

What is Percent (%) Reflectance?![]()

Reflectance is a measurement of the amount of light detected versus the amount of light sent and is expressed as a percentage. Gloss meters such as the PosiTector GLS can display in both GU and percent reflectance directly on the gage.

![]() What is Gloss Value? What are Gloss Units?

What is Gloss Value? What are Gloss Units?![]()

Per ISO 2813, Gloss Value is a ratio of the reflectance of the test specimen to the reflectance of a standard polished black glass surface “with a refractive index of 1,567 at a wavelength of 587.6 nm in the specular direction”, multiplied by 100. It is expressed in terms of Gloss Units.

![]() What is Haze Index?

What is Haze Index?![]()

Haze is the appearance of a “milky” halo or bloom perceived in reflective surfaces caused by microscopic imperfections in the surface’s texture. Haze Index is calculated and is defined by ASTM D4039 as the difference between gloss values measured at 60° and 20°. The PosiTector GLS 20/60 and 20/60/85 are capable of calculating haze when selected within the Setup menu.

![]() How is Gloss Measured?

How is Gloss Measured?![]()

Digital gloss meters like the DeFelsko PosiTector GLS Gloss Meter measure the surface using a calibrated light source and light sensor at opposite, specular angles to each other. Reflectance is determined by comparing the amount of light energy emitted by the source with the amount of energy received by the sensor. Gloss is then automatically calculated using a look-up table.

The PosiTector GLS Gloss Meter includes a reference standard built into the base of the unit. When turning the unit on or when selected from the menu, the instrument automatically calibrates itself using the known Gloss Unit values of the standard.

![]() Choosing the Best Angle for Gloss Measurement

Choosing the Best Angle for Gloss Measurement![]()

On most surfaces, as the viewing angle increases, the reflectance and Gloss Value also increase. This is often apparent to the naked eye: for example, on the case below there is little apparent reflectance when viewed from above, but when that same case is viewed from a wider angle (nearer to the surface), visible reflectance can be seen. This phenomenon can be used to provide greater measurement resolution on high-gloss and matte finishes. |

To determine the correct gloss measurement angle, gloss is first measured at a 60° angle:

- If the result is between 10 - 70 GU, the object in question is considered semi-gloss and the 60° measurement angle is appropriate.

- If the result is greater than 70 GU, the surface is considered high gloss and should be measured with the 20° angle.

- If the result is less than 10 GU, the surface is considered matte and should be measured with the 85° angle.

![]() How to take Gloss Readings with the PosiTector GLS Gloss Meter

How to take Gloss Readings with the PosiTector GLS Gloss Meter![]()

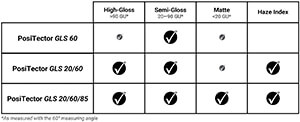

The PosiTector GLS Gloss Meter is available in three models:

|

Taking gloss measurements with the PosiTector GLS Gloss Meter is fast and easy:

|

|

|

![]() Features of the PosiTector GLS Gloss Meter

Features of the PosiTector GLS Gloss Meter![]()

The PosiTector GLS boasts multiple measurement modes and helpful features that make it suitable for nearly any application:

- HiLo mode: for quick inspection or pass/fail checks

- Differential Mode: automatically calculates the difference between current reading and stored reference value*

- Normal Scan Mode: measure and save up to 120 readings per minute*

- Statistics Scan Mode: continuously measures and displays real-time statistics, saving each scan into memory*

- Alternate Calibration Standards: store multiple calibration standards (tiles) for quick calibration adjustment

*Available on PosiTector GLS Advanced models only

Since it is part of the PosiTector platform, the PosiTector GLS is compatible with any PosiTector probe; quickly converting from a gloss meter to a coating thickness gage, surface profile gage, environmental meter, and more. It also has the added benefit of a large 2.8” impact resistant color touchscreen, and an easy-to-use menu. Advanced gage bodies can connect to personal smart devices or laptops via WiFi or Bluetooth.

![]() Manage Gloss Measurement Data with PosiSoft Software

Manage Gloss Measurement Data with PosiSoft Software![]()

| When gloss inspection is complete, download the readings using the built-in USB port, or via WiFi if using an Advanced gage body. When connected, download, view, and print stored readings in professional PDF reports quickly and easily with PosiSoft Desktop software. Fully customized reports can be created to match existing paper forms or layouts. |

How to measure gloss using the PosiTector GLS Gloss Meter, from DeFelsko - the measure of quality. Gloss is an optical property that indicates how well a surface reflects light in a specular, (mirror-like) direction. It refers to how lustrous or shiny an object appears, generally affecting it’s aesthetic and perceived value. On high-gloss surfaces, light is reflected at the angle of incidence. On matte surfaces, the light is diffusely scattered in all directions. |

Several factors can influence the gloss of a product, including texture, coating properties, and paint application.

By taking gloss measurements, process issues and defective parts can be identified - maximizing consistency, reducing waste, and improving quality.

Gloss is typically measured and reported in Gloss Units or “G.U.” as defined by standards such as ASTM D523 and ISO 2813.

Additionally, some gloss meters, like the PosiTector GLS, are capable of measuring Reflectance and Haze Index.

Reflectance is a measurement of the amount of light detected versus the amount of light sent and is expressed as a percentage.

Haze is the appearance of a “milky” halo or bloom perceived in reflective surfaces due to microscopic imperfections.

The ‘Haze Index’ is measured according to ASTM D4039 by subtracting the 20° from the 60° specular gloss measurements.

Because of the vast range of gloss values, different measurement angles are used to provide the best resolution across matte, semi, and glossy samples.

The 60 degree measurement angle is the recommended starting point, and is used to measure many common finishes such as interior wall paints, furniture, packaging materials, and plastics.

Finishes that read greater than 70 GU at the 60 degree measurement angle are considered high-gloss, and should be measured using a 20 degree measurement angle. These finishes are often seen on cars, traffic signs, and other applications where a reflective or mirror-like finish is desired.

Finishes that read lower than 10 GU at the 60 degree measurement angle are considered matte, and should be measured using the 85 degree measurement angle. Gloss measurements in this range are commonly seen on products such as fabrics, leather, and military assets.

The PosiTector GLS Gloss Meter is the ideal instrument for quality control specialists. Three probe models are available.

The PosiTector GLS 60° is suitable for most gloss applications and is the preferred angle for measuring semi-gloss.

The PosiTector GLS 20°/60° is ideal for high- to semi- gloss applications and has the ability to calculate haze index.

The PosiTector GLS 20°/60°/85° is suitable for all gloss applications - high-, semi-, and matte. It is also capable of calculating haze index.

When powered on, the probe performs an automatic self-check and calibration using the calibration standard incorporated into the protective base plate. A traceable certificate of calibration for both the probe and standard are included.

For some applications, it may be desirable to calibrate the probe to a different calibration standard. Easily add and manage up to 99 different standards.

The durable all-metal probe is designed for long term stability and a long service life. It is connected to the PosiTector gage body via cable, making it ideal for measuring tight or awkward applications.

The PosiTector gage body is also compatible with any PosiTector probe, quickly converting from a gloss meter to a coating thickness gage, surface profile gage, environmental meter, and more.

Two gage bodies are available:

The Standard gage body is compatible with all PosiTector GLS probes, has a HiLo Alarm mode, and can display on-screen statistics such as the average, standard deviation, min/max, and number of readings while measuring, storing up to 1,000 readings.

The Advanced gage body includes all of the functionality of the standard model, plus storage of up to 250,000 readings in up to 1,000 batches and additional functionality such as scanning and differential modes:

By default, the PosiTector GLS is capable of measuring 1 reading per second.

With Normal Scan Mode enabled, it is capable of continuously measuring and saving up to 120 readings per minute.

With Statistics Scan, the probe continuously measures and displays real-time scan statistics, saving only the statistical summary for each scan into memory.

For quick inspection or for pass/fail checks, HiLo mode visibly and audibly alerts the user when measurements exceed user-specified limits.

Differential mode automatically calculates the difference between the current reading and a stored reference value - ideal for comparing results to a known target value.

Taking gloss measurements with the PosiTector GLS Gloss Meter is fast and easy.

Power the gage on with the center navigation button.

The PosiTector GLS will automatically perform a calibration every time the gage is powered on. Be sure that the probe is fitted into the included protective base plate with integrated calibration standard.

Periodically, or when dust or debris is visible, the gloss standard should be cleaned using the included cleaning wipes. Ensuring the standard tile stays clean is critical to ensuring the accuracy of the meter.

The PosiTector GLS is now ready to measure.

Remove the protective base plate from the probe and place the probe on a firm, flat surface.

Simply press the button to take a reading. When a measurement is obtained, the gage beeps twice and the measurement is displayed.

When inspection is complete, download the readings using the built-in USB port or alternatively via WiFi or Bluetooth if using an Advanced gage body.

When connected, download, view, and print stored readings in professional PDF reports quickly and easily with PosiSoft Desktop.

Fully customized reports can be created to match existing paper forms or layouts.

The new PosiTector GLS Gloss Meter is the simple, durable, and accurate way to measure gloss.

With an easy-to-use interface, fast measurement speed, onboard memory, and easy reporting solutions - all backed by DeFelsko’s renowned quality, customer service, and exceptional two-year warranty - the PosiTector GLS Gloss Meter is the ideal choice for gloss measurement.

![]() Conclusion

Conclusion![]()